In the fall of 1964 Banana (Lowell Levinger), Michael Kane, and I moved to Cambridge from the Vineyard into a second story apartment off of Putnam Ave. The spot was near the Charles River in an area about equidistant from Central Square and Harvard Square. We were gone from Boston University, and we were living the folkie Bohemian life in one of the best places to do that in the US. Rent was cheap, we could walk anywhere in town, and there were always friends like Paul Arnoldi or Jim Mairs who had cars if we needed or wanted to go anywhere the subways and busses didn’t go, and beyond that, hitchhiking was an accepted and reasonably safe way to get to New York, Providence, or wherever. I remember us hitching out to U Mass to see Bob Dylan perform, and we got a ride from a woman who turned out to be involved with putting on a folk festival out there. We wound up staying with her and her husband, played well into the night, and her only request was that we not bring any pot to the festival. Pot? Us? No way…never heard of the stuff… Yeah, sure…

I don’t know what Michael and Banana did for money in those days, but I had a real job, working at Briggs and Briggs, an old time full line music store in Harvard Square. They sold records and had three listening rooms for auditioning the latest albums. They also had an incredibly extensive selection of sheet music all stored in a wall of filing cabinets behind the counter, and I, with practically no education in classical music, quickly learned to fake it and find the sonatas, concertos and the like being sought by Harvard students. And down stairs were two rooms with guitars…Gibsons, Epiphones, Guilds, and Harmonys, and since I was the young guitar player, I got to be the guitar salesman, too. To top it all off, on my way to work lived my first post high school serious girl friend, an “older woman” three years my elder who was a local folk singer playing all the clubs in Boston and Cambridge. Nancy introduced me to the joys of French press coffee and sex in the morning before going to work. For a preppy turned acoustic guitar player that was pretty cool stuff all around. Sometimes I stayed with her, sometimes back at the musician’s boarding house that our apartment had become. It was right out of “Tangled up in Blue.”

It was about this time that I first tried psychedelics in the form of extract of heavenly blue morning glory seeds, courtesy of Maria Muldaur who had given a jar of this vile gray glop to my friend Diane Tribuno, later to be married to bluesman Nick Gravenites. Diane, Jim Mairs and I did the whole 1964 ritual…we read from the Tibetan Book of the Dead, we lit incense, we put on Bach organ fugues on Diane’s record player, and then we all took a trip, and it was the real deal. Laughter, visions, intense profound revelations…at least they seemed so at the time, and just one hell of a good time.

In those days there was a new tradition in Cambridge of psychedelic exploration. Richard Alpert, better known now as Ram Dass, and Timothy Leary had been teaching at Harvard and in the late 1950s they became academically interested in the effects of psychedelic drugs, particularly on creativity. This whole thing blew up in their faces, and in the spring of 1963 Dr. Alpert was fired from his job, and he and Leary headed for Mexico under a cloud of scandal…and were promptly unofficially declared the patron saints of the whole psychedelic revolution into the back yard of which we had dropped. We all regarded acid as a combination of sacrament, brain opener, and, well, fun.

A few weeks after my first trip a number of us decided to try LSD and go see Hard Day’s Night for the first time. Three of us would take the acid before seeing the film, three would wait to see if we killed ourselves or anything and get a report from the other side before downing their doses. I was in the first wave, and what can I say? It was wonderful, spectacular, those guys were having so much fun just goofing off that we all never wanted the movie to end or we wanted to step into the screen, or, and this is what really happened, we wanted to live life as large as we possible could, get paid for it, and just keep going for the rest of our lives. The movie, of course, came to an end, and out we stumbled, by then six stoned musicians coming out into a nice snowfall. For some reason we decided to go over to Bill Lyons’ house and get him stoned too. Bill was a balladeer around the clubs and sometime guitar repairman. He was a bit of a curmudgeon, he was gay, and he was fun to hang out with having a wicked sense of humor and having been around the Boston Cambridge folk scene since the very inception. To get to his place we had to go down a moderately steep drive way to part in back of the house which we did only to find him not home. So we piled back into the car, probably Jim’s Volvo, and headed for the street. No go. The snow and a light sheet of ice had glazed over the driveway, and we only made it up about half way and then started sliding back. What to do? Back up a bit further, gun it, and try for the top. No go. Back a couple more feet further, and hit it. No go. Well this went on for a good half hour. We were cracking up so much that we didn’t dare get out of the car to try to sweep off the snow or through sand out or get a shovel or do any of the things that normal sane people would do. The problem was that we were abnormal and insane and we knew it. Of course it didn’t occur to us that a neighbor might wonder why a car full of proto-hippies with exploding heads was repeatedly attacking a snowy hill with a Volvo. Too much fun, and the next phase of a pretty good run.

Banana, Michael and I sold a bit of pot and we had a fantastic connection for Sandoz LSD that a guy in a Cadillac would deliver. Up the stairs he’d come with a briefcase full of glass ampules of brown liquid acid of the highest quality from the folks who invented the stuff. We’d pipette it onto sugar cubes, and move it on.

The apartment became a real hangout for musician/psychedelic connoisseurs and we continued to have out of town musicians stay with us there. One of them was Monte Dunn, guitar accompanist to Ian and Sylvia whom we had met in the summer of 1964 when they played at the Moon Cusser. We’d all hit it off, and played a lot of music together, an eclectic blend of folk, Bluegrass, and what would become known as folk rock.

Another regular, but relatively local was Peter Rowan, a great Bluegrass singer and guitarist drawn into the scene. We got along famously with Peter, and when his draft notice came, we all got together to strategize how to convince the draft board that Peter was unfit for service. Bear in mind that we didn’t even know about Vietnam at this point. We hear vague rumblings of things going badly in South East Asia, and we were for the most part Seegerized anti-war peaceniks, but we weren’t yet anti-Vietnam war protesters. We just didn’t want our pals or ourselves to be pushed into the army to be trained to kill for no particular reason other than corporate maneuverings and politics.

At that point in time, the standard ways to be declared 4-F were to show up without any underwear and unwashed for a few weeks, say you were queer, or appear to be a drug user, They hadn’t yet figured out that half their army was about to be drug users and that they could just throw stoned soldiers at the front lines. So we decided to give Peter a good dose of acid that he would take right before going for his draft physical. Well, it worked, and how! Peter went in a mumbling lunatic without having to do very much acting. They basically threw him out on the street whereupon the legend is that he found a Macy’s department store pet shop and started to let the birds go free from their cages, just as he had been let free. Ask Peter about that the next time you see him…

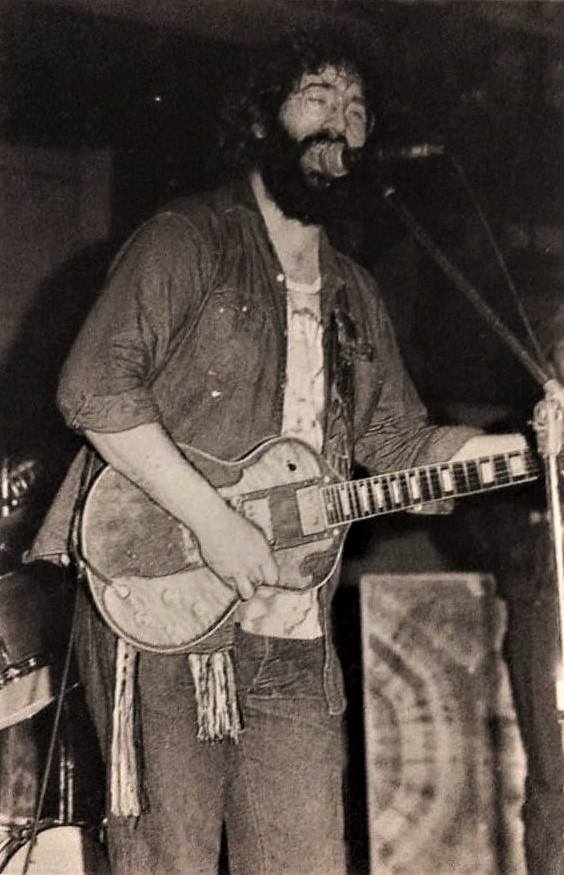

Island String Shop, summer ‘64

In the spring of ’64 Lowell “Banana” Levinger, Michael Kane, and I, room mates in Brookline where we were busy dropping out of Boston University, were at a party at the apartment of Dick Randlett, co-owner of “The Mooncusser Coffeehouse” in Oak Bluffs on Martha’s Vineyard. Dick was an electronics designer by day and folk music fan at night; he and his partner, Charlie Close were gearing up for another summer on the Island with a great line up of booked talent. Banana and I got the idea of opening a music store in a part of the building that had it’s own store front and backed up to the Mooncusser’s kitchen. The store was on a side street in Oak Bluffs, right next to an incredible Portugese bakery and two doors from the post office. It was a perfect setup for us; it was about 250 square feet, had nice windows flanking the door, and had great light. Rent was cheap…Banana negotiated a percentage of our net. No net, no rent, and we were indeed doing acrobatics without a net!

Banana and Michael were making music with John and Jane Nagy as the Proper Bostonians, and they all needed a summer out of the Boston scene to practice. Banana found us a great huge apartment above an African American beauty salon about a block and a half from the club. We painted the apartment totally weird colors, which bothered Jane, but she got over it, and so we all moved into this place, none of us having the slightest idea of how we were going to do financially. And that should have been a worry, as the store was a disaster from that point of view, but we really didn’t care. We had access to all the coffee we could drink, a “day gig” which consisted of hanging out and doing a little bit of guitar repair work, and nights in the club where we were the house band, and I washed dishes for spare change. How we paid the rent I don’t recall, maybe it was from the proceeds of selling some pot, but there was a day when we were happily broke, figured we needed protein, and there it was, canned mackerel kind of down at the end of the cat food section in the market. It wasn’t labeled pet food, but it sure was cheap. We bought it, ate it, and prospered.

The week before the Newport Folk Festival was to take place, we were so broke that I doubt that among the three of us we could have scraped up the fare to get one of us off-island, and that was of tragic proportions in our lives. The lineup of talent, both on the old traditional side and the city folks and up and coming talents like Bob Dylan was incredible, and we couldn’t go. Life at the club was good, though, Jim Kweskin’s Jug Band with Jim, David Simon, Mel Lyman, Fritz Richmond, and the Muldaurs, Geoff and Maria were tearing up the nights. They were at one of their several peaks of performance that summer, and they had a lot of fans on the island. One of them happened to be a yachtsman, and he popped into the dressing room downstairs from the kitchen and our store and announced to us all, “Hey, I’ve got a 45 foot cabin cruiser and I’m headed for Newport. Anyone want a ride?” I hope he wasn’t too shocked at how many takers he had, because we all wanted on-board, and so it was. Diane Tribuno, she of my first acid trip, was hanging out with me, not as my girlfriend, but just as a pal, so she was literally my bunk mate; Banana and Michael and most of the Kweskin band came along, and so it was that we arrived in Newport with a floating hotel for the duration of the weekend and a ride back. The only problem was that we didn’t have tickets. Diane was fine; I think she had scored tickets weeks in advance; the band was fine, of course, as they were playing the festival; Banana, Michael, and I just figured on figuring it out even if it meant slipping under a fence like kids sneaking into a big top circus. No need…the first person we saw upon walking up to shore from the dock was Bernie Apothecker, a folk scene gig hustler from Boston who was to become Peter Rowan’s manager for a while. We knew Bernie through John Nagy, and had hung out with him quite a bit.

“Hi, guys, whatcha up to?”, Bernie called to us. I said, “Just got here on that boat, and we’re trying to figure out how to get into the festival.” “Oh, no problem…I’m in charge of giving out press passes and I have them all here in my pocket. Who is going to be who? OK, Banana, you represent the BU paper; Michael, you’re from Brandeis, and Rick, you write for the Boston College daily!”

And so we got to enjoy the festival in style…full back-stage access, first five rows of main stage seats, food, the after-show parties in the little Newport “cottages”…the whole thing. And little did I know that the next year, 1965, would see me playing on the main stage with the Canadian duo, “Ian and Sylvia”, some of that set now immortalized on a Vanguard recording, “Ian and Sylvia, Live at Newport”.